Bar & Plate vs. Tube & Fin

Flat tube heat exchanger can be manufactured in two different ways. On the one hand there are the Bar & Plate - intercooler and on the other hand the Tube & Fin - intercooler. But what are the differences and where are the advantages and disadvantages?

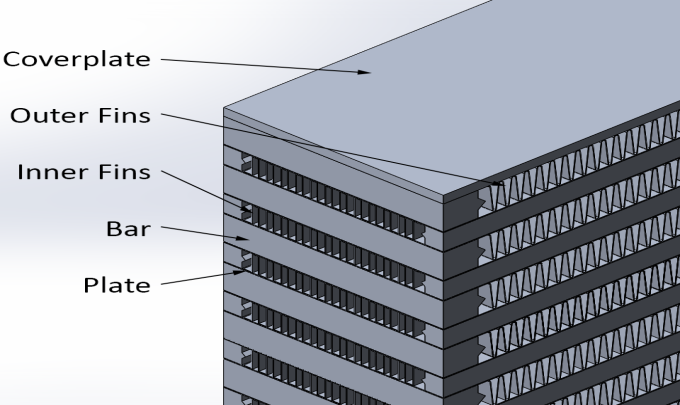

Bar & Plate nets are basically just solid „bar’s“ and „plates“ assembled in a simple stacking construction.

In this way, the fluid areas (for example between the charge air and the airstream) can be very easily separated from one another and are also provided with heat-dissipating fin structures („fin’s“). The manufacturing costs are comparatively low, but due to the massive bars and plates are also associated with very high material costs. This high material input results in the fact that a Bar & Plate net behaves highly inert thermally. Therefore, at the first moment of temperature absorption, the base material alone is capable of absorbing a relatively large amount of temperature. Once it has warmed up, however, it is difficult to get rid of this thermal energy. The main application of a Bar & Plate net is generally in the industrial sector. For vehicles with rapid load changes and higher requirements, the Tube & Fin concept is increasingly the preferred option.

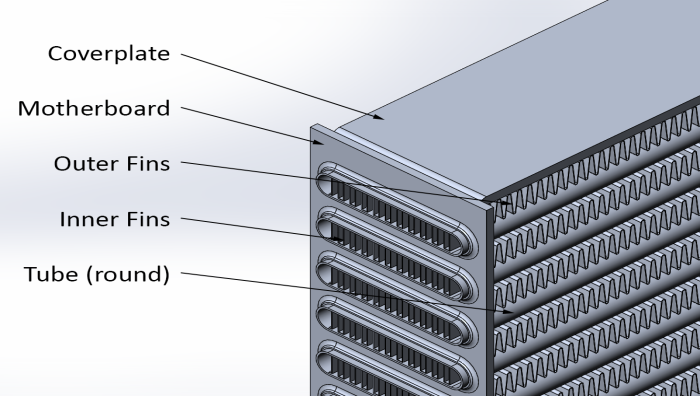

Tube & Fin nets are characterized by a very filigree structure. Thin-walled channels (the so-called "tubes") are firmly connected to a carrier plate ("motherboard").

The heat dissipating lamellar structures ("fins") can thus be placed both between the tubes ("outer fins") and inside the tubes ("inner Fins"). Together with the "coverplates", which provide stability, this results in a net structure that requires very little material. This low material input ensures that the net can absorb temperatures very quickly and also release them again very fast. This makes it ideal for permanently changing load conditions, such as in the automotive sector. Also, this reduces the total weight compared to a same sized Bar & Plate net by approximately 30%! Another advantage of Tube & Fin nets is the rounded tubes, which allow an ideal diversion of the flowing medium, in contrast to the hard edges and surfaces found in Bar & Plate Nets.

However, due to the considerably more complex technological effort involved in the production of a Tube & Fin net, comparatively higher production costs are also incurred. This is a factor that acts as a deterrent for many small series manufacturers.